hard plastic

Following the problems encountered with Resin dolls, Peggy Nisbet realised that a more stable material, and a more reliable production process had to be found.

In 1957, Peggy started to investigate the use of injection moulding, to produce high impact polystyrene doll bodies. (This material is often referred to as Styrene, or Hard Plastic).

Because Peggy wanted the dolls to have weight and solidity, the usual process of moulding two thin plastic "shells", which were then glued together, was rejected in favour of a solid plastic body. When moulding the larger (Henry VIII) male body, there was a potential for the plastic to shrink as it cooled, especially in the thicker (stomach) area of the doll. Thanks to the use of a skilful moulding company, this problem was overcome.

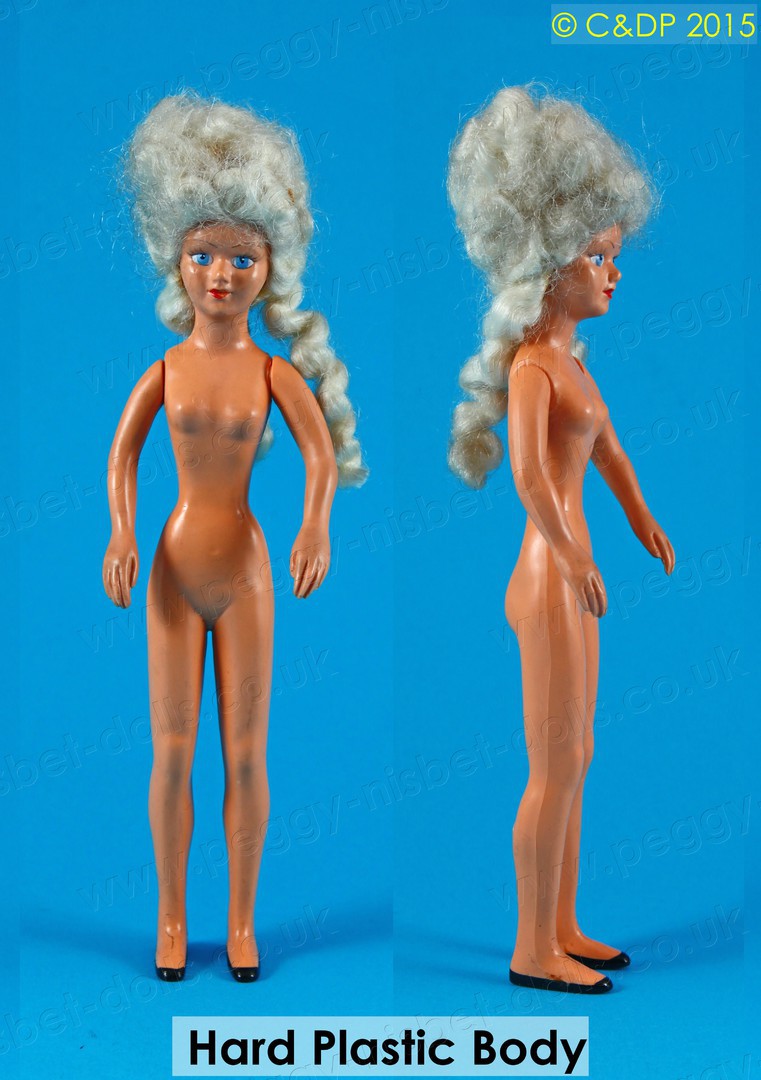

Peggy was very particular about the colour of the plastic used to mould the bodies, rejecting many supposedly "flesh" coloured varieties, that ranged from "deep sunburn" through yellow, buff, and pink, before settling on the colour seen on any of the Historical, Portrait, Limited, or other hard plastic dolls shown here. Also very important to Peggy was to select a grade of plastic that came out of the mould without too hard a shine, which would have made the doll look unnatural.

We believe that dolls made from Styrene first went into production in 1959/60